Customer Services

Copyright © 2025 Desertcart Holdings Limited

⚙️ Elevate your CNC game with power, precision, and peace of mind!

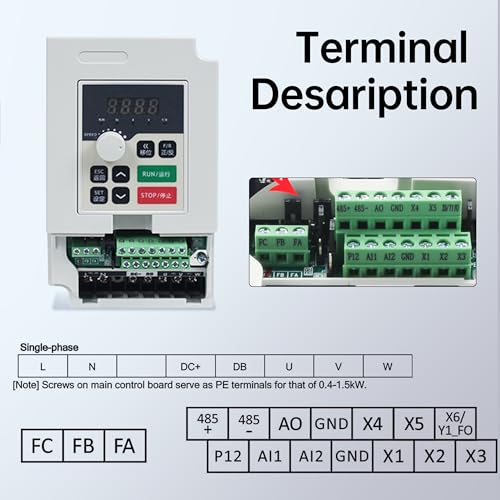

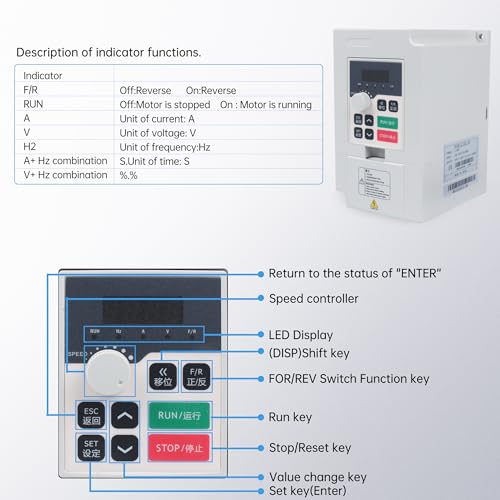

The RATTMMOTOR 2.2KW CNC Spindle Motor Kit combines a high-speed 220V air-cooled spindle with a robust variable frequency drive (VFD) featuring comprehensive fault protections and advanced control functions. Designed for professional CNC routers and milling machines, it delivers up to 24000 RPM with exceptional precision (runout <0.01mm) and stability, ensuring efficient, safe, and accurate machining performance.

| ASIN | B09NVW8ZN6 |

| Are batteries included? | No |

| Brand | RATTMMOTOR |

| Customer Reviews | 4.8 4.8 out of 5 stars (10) |

| Date First Available | 5 August 2023 |

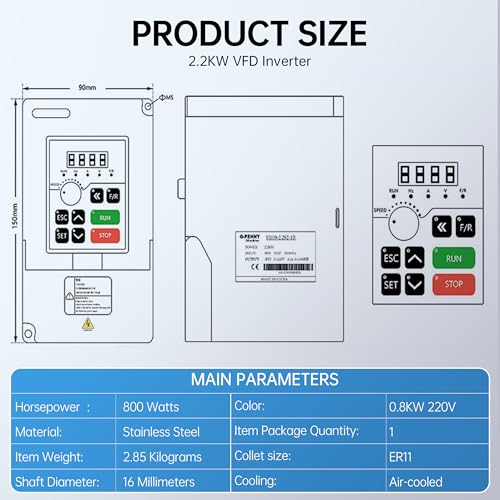

| Horsepower | 2.2 Kilowatts |

| Item Weight | 4 kg 900 g |

| Item model number | CFFK-2.2RTM |

| Manufacturer | RTM |

| Material | Stainless Steel |

| Model Name | CFFK-2.2RTM |

| Model number | CFFK-2.2RTM |

| Product Dimensions | 10.9W x 10.9H Centimeters |

| Shaft Diameter | 1.22 Inches |

| Speed | 24000 RPM |

| Voltage | 220 Volts |

A**R

Wired it up, works well. No programming required on supplied drive, plug and play. Seems to have plenty of power for my application.

K**6

There are 2 prices in the listing with no explanation of the difference. I bought the cheaper one not knowing that it is a 2.2k spindle but with a 1.5K VFD. The more expensive one has a 2.2k vfd from what I can tell. It runs fine with the 1.5 so far but I would have liked to know that before buying it, it could have easily been clearly stated in the listing. I was able to download a file from their website with some more useful information on the wiring of the VFD. They had sent me an email after purchase which seemed to suggest not to ground the spindle but I think I just cant understand the translation of what they were trying to say. I studied the wiring diagram quite well before starting and my testing went flawlessly. I screwed the VFD and the spindle to a piece of plywood for testing in case of any motor torque related movement of the spindle. I also tightened a dowel pin into the collet so nothing would go flying. For example the collet nut as you never know if the spindle will start clockwise or counter clockwise the first time or what RPM it will start at. No flying nuts wanted. Its ok to take the nut off and set it aside too but I would be afraid to misplace it. While anyone can wire one of these to some degree and get it working, its worth noting that there are lethal voltages present and exposed after completion of the wiring on the VFD. The VFD should be installed after testing in a suitable enclosure, not on a wall or directly on a machine. Chips, dust, debris, or any object can find the contacts and cause all kinds of unwelcome events that are harmful to nearby people and property. People and objects can also come in contact with something inadvertently that can cause injury or death. Sorry for the safety rant but I have seen so many of these installed in weird places with bad wiring and so on. I saw one installed inside a machine enclosure with the machine! The dimensions for the spindle mounting holes are not all listed anywhere I found so my measurements are- the 7mm diameter holes are 35mm spaced and 95mm side to side. They measure pretty close to those numbers.

D**L

Se siente de buena calidad, buenos materiales, muy bien diseñado pero lo devolví porque es muy pesado para mi maquina

Trustpilot

3 days ago

1 week ago