Customer Services

Copyright © 2025 Desertcart Holdings Limited

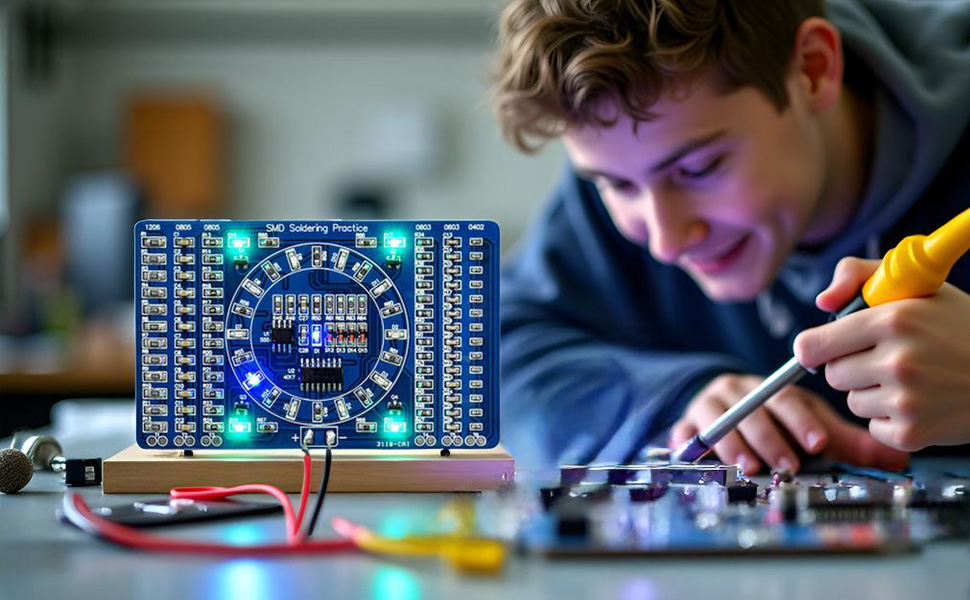

🔥 Master the art of precision soldering — light up your skills with every connection!

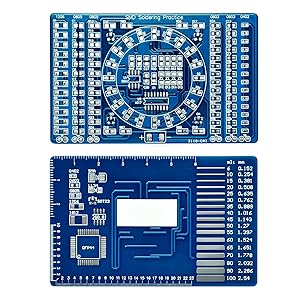

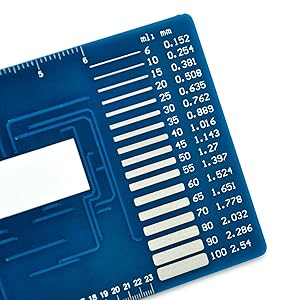

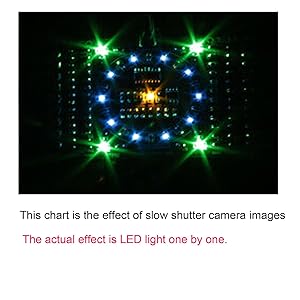

The Gikfun DIY SMD SMT Welding Practice Board Ek7028 is a compact, beginner-friendly training tool designed to sharpen your surface-mount soldering skills. Featuring a high-quality PCB with clearly marked components and an integrated ruler, it allows instant visual confirmation of your work via a powered water lamp circuit (3-12V). Ideal for professionals and hobbyists alike, this board offers a progressive learning experience in a sleek, portable format.

| ASIN | B00VWB8F8K |

| Are Batteries Included | No |

| Best Sellers Rank | #29,389 in Tools & Home Improvement ( See Top 100 in Tools & Home Improvement ) #154 in Soldering & Desoldering Equipment |

| Brand | Gikfun |

| Color | Blue |

| Computer Memory Type | DDR4 SDRAM |

| Customer Reviews | 4.2 4.2 out of 5 stars (744) |

| Date First Available | 4 January 2016 |

| Graphics Card Description | Dedicated |

| Graphics Card Interface | PCI Express |

| Graphics Chipset Brand | Intel |

| Graphics Coprocessor | [SEPARATE DEDICATED GRAPHICS COPROCESSOR] |

| Graphics RAM Type | Unknown |

| Hard Disk Description | SSD |

| Hard Drive Interface | Serial ATA |

| Hard Drive Size | 1 TB |

| Item Weight | 9.07 g |

| Item model number | LYSB00VWB8F8K-ELECTRNCS |

| Manufacturer | Esooho |

| Maximum Memory Supported | 1 GB |

| Memory Technology | DDR4 |

| Processor Brand | Intel |

| Processor Count | 4 |

| Processor Type | AMD Ryzen 7 |

| Product Dimensions | 12.7 x 8.13 x 0.25 cm; 9.07 g |

| Resolution | 3840x2160 |

| Screen Resolution | 3840 x 2160 |

| Series | Ek7028 |

B**C

This little board is laid out in a way that makes surface‑mount practice feel approachable, even if you’re just getting comfortable with smaller components. The instructions are easy to follow, the pads take solder well, and the mix of part sizes gives you a nice progression as you work through it. It’s a quick, low‑stress project that helps build confidence with SMD techniques and offers a satisfying result when finished. A solid choice for sharpening fine‑detail soldering skills

M**L

Although I think this could be cheaper I think it gets the job done for learning new skills or brushing up on old ones. I bought this to brush up on some soldering after some time leaving university doing electronics. I thought it was a good quality board. Easy enough to do with some patience. I used 0.6mm diameter solder with a thin tip iron and a pair of helping hands. I say easy enough to do I have bought 3 of these since the first two I messed up. Put the polarity of some components the wrong way round and second one put the battery the wrong way round... Best to check to be sure to save yourself money. Instructions arent as easy to follow as they could be but all works one you finished.

M**O

È buono ma potevano essere 5 stelle ma no si capisce gli smd da montare non sono spigati i valori e come montarli

A**.

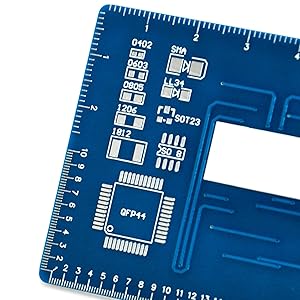

I was very positively surprised by the quality of the included PCB. It's relatively thick, feels very solid, and has very good quality solder mask applied to it. The components themselves came in the usual stripes cut from reels. For most component types, few more were provided then needed, making things easier if one of the SMD components gets lost. The kit comes with a small printed manual, written in English language, which provides basic information on how to do surface-mount soldering, and has several illustrations explaining the steps needed to solder the components, how to identify the correct orientation of the included integrated circuits and diodes, and includes the schematic of the LED Blinker located in the middle of the PCB. The back side of the PCB has several rulers, in centimeters and in 1/10ths and 1/100ths of an inch, as well as examples of several popular PCB trace widths, and popular component footprints. As for the bad sides, there are few small points: The manual seems to be translated from Chinese. In general, grammar of the translation is very good, and manual is easy to understand, however few technical terms have been incorrectly translated: The manual always refers to the procedure as welding, instead of soldering, and it refers to the transistors as triodes. The direction of the SMD LEDs is not shown on the silkscreen, so it needs to be manually determined by following the traces on the board and using the included circuit schematic. Additionally, the measurement unit of 1/1000 of an inch is misspelled as mli instead of mil on the back side of the PCB. All in all, this is a great kit, but it does require some very basic knowledge of electronics.

H**C

I solder for over 50 years by now - now way less these days, but I felt for small repairs you need to work with SMD's, and so far I guess I was lucky. As the saying goes, practice makes perfect, and I can see my solder joints improve with every new component, and I can work out what works for me in placing and holding, etc. One issue with THIS kit I received, the 402 components are missing, annoying but I am not sure if I could freehand solder them anyway - but it would have been good to try. Had the kit for a few months before I spent time with it, so I did not complain to the vendor, who knows, they may have rectified it if I had. Update: when building the rest of the kit i found the 402 components in the other sealed bag.

Trustpilot

2 months ago

2 weeks ago