Customer Services

Copyright © 2025 Desertcart Holdings Limited

Desert Online General Trading LLC

Dubai, United Arab Emirates

🎸 Elevate Your Sound with Precision Craftsmanship!

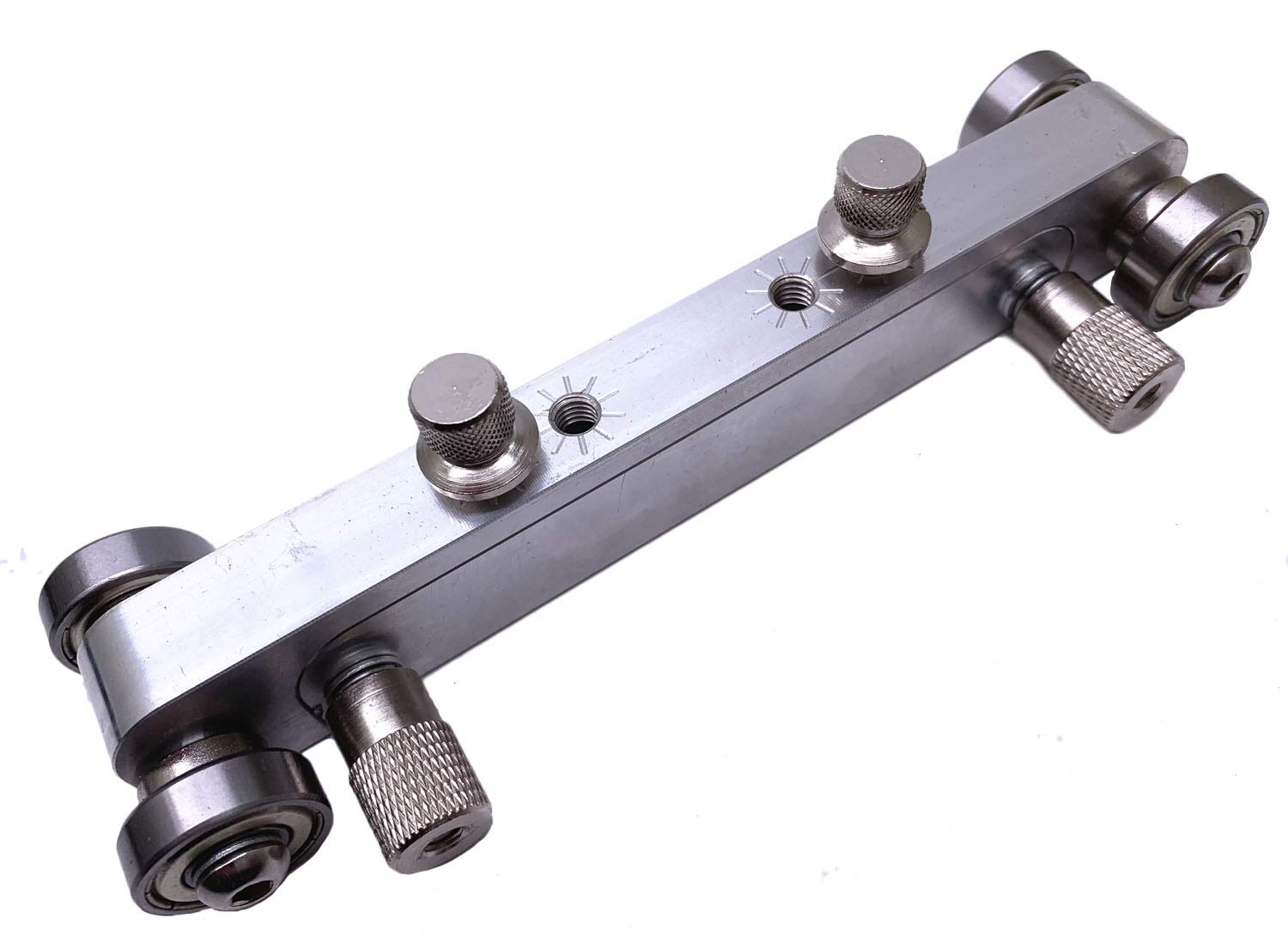

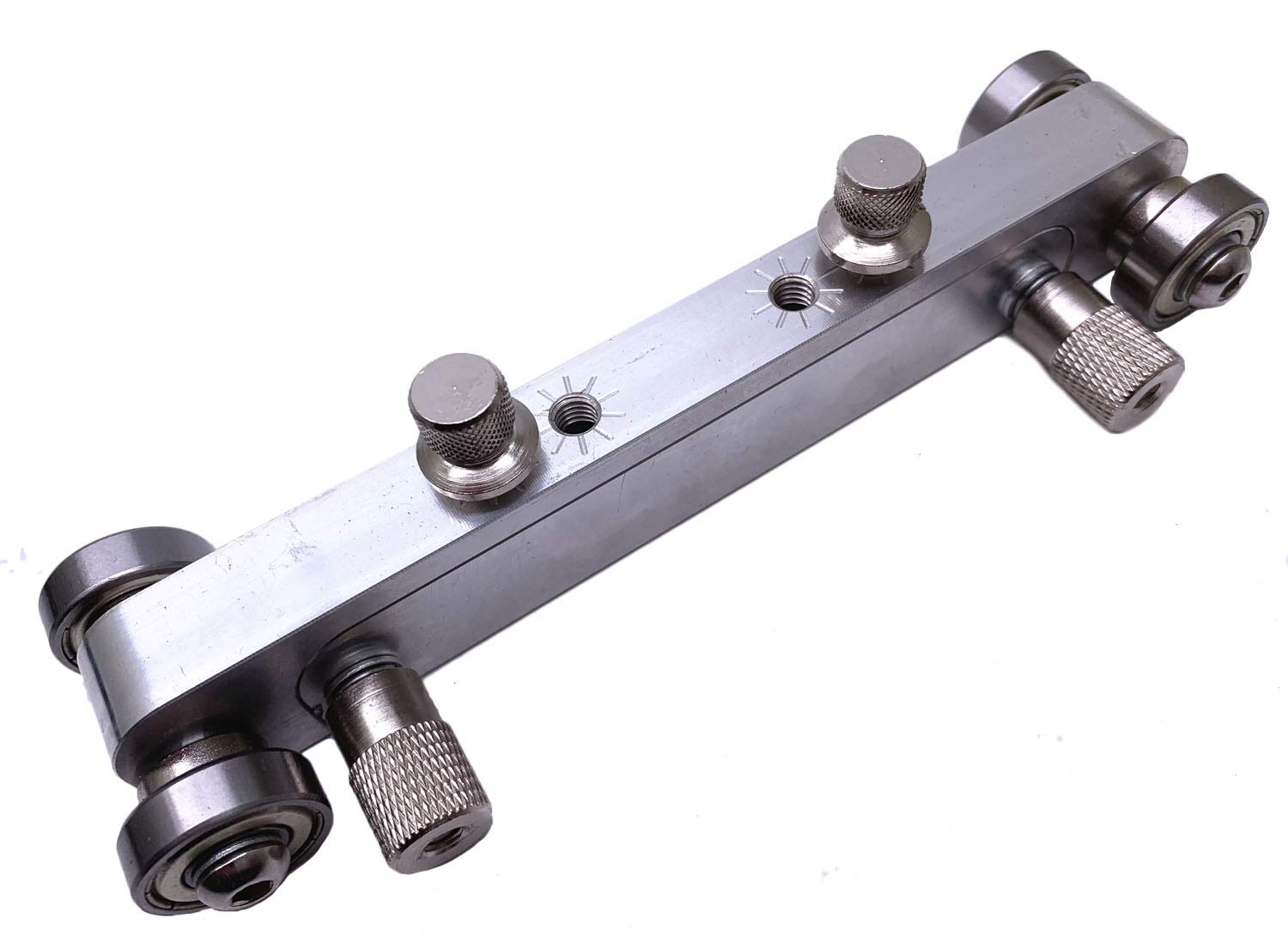

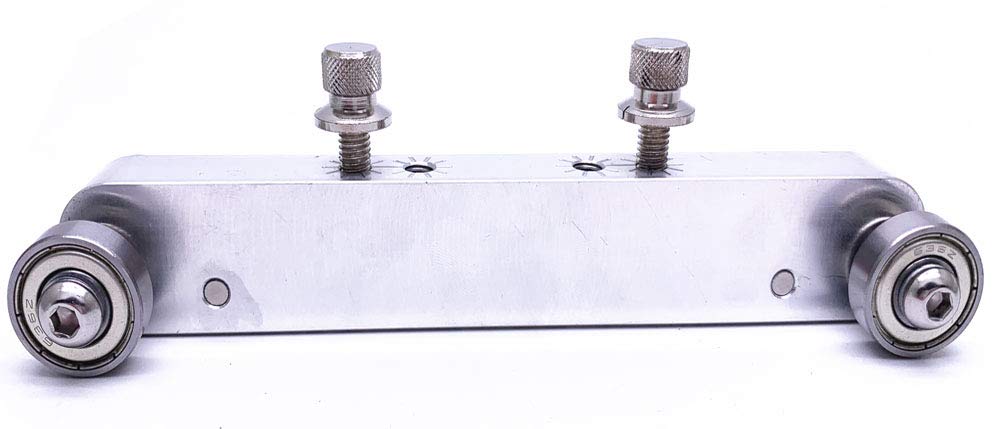

The Jiayouy Adjustable Guitar Nut & Bridge Sander is a professional-grade luthier tool designed for electric and acoustic guitars. Its aluminum alloy body and durable steel ball-bearing rollers ensure a smooth and efficient sanding process, while the adjustable height feature allows for precise customization. Ideal for polishing various nut and saddle materials, this tool is essential for achieving optimal guitar performance.

Trustpilot

3 weeks ago

2 months ago